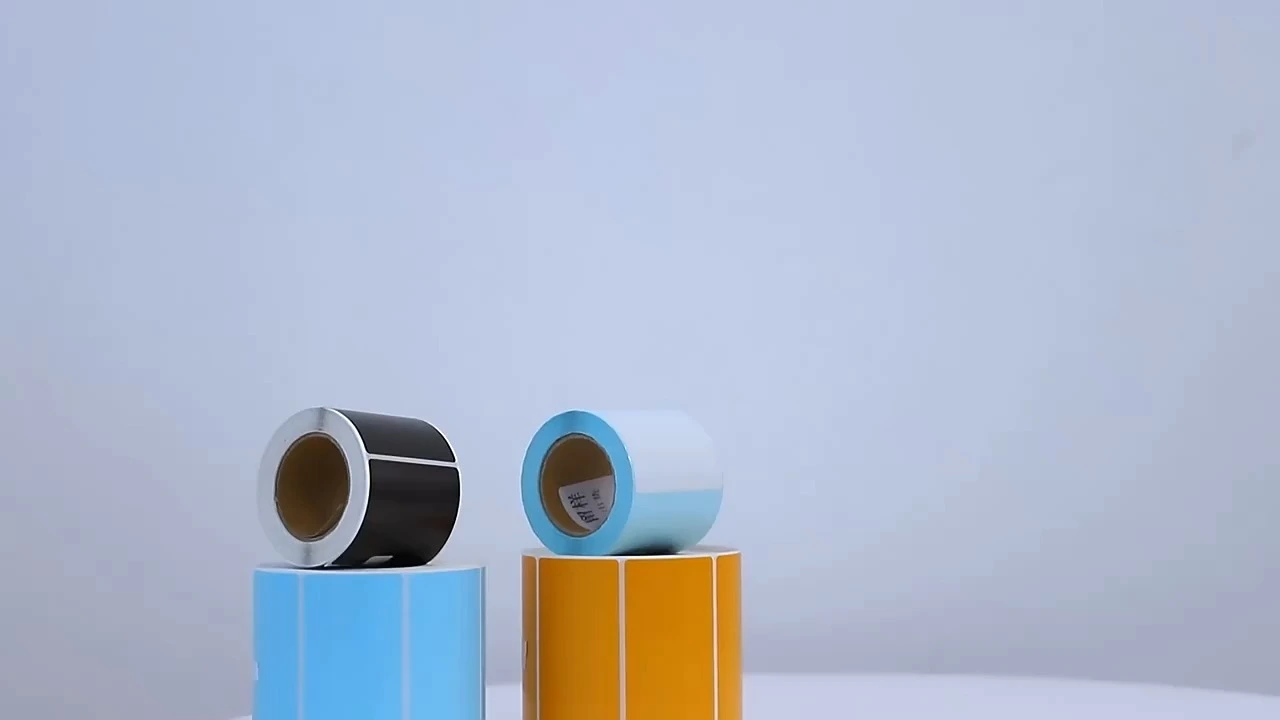

Film Labels & Thermal Transfer Ribbons

Product Introduction

Film labels are synthetic labels made from materials like PET, PP, PE, and PVC, offering superior weather resistance, chemical durability, and mechanical strength compared to paper labels. They are ideal for harsh environments, including high temperatures, moisture, oil exposure, and outdoor conditions.

Thermal Transfer Ribbon for Film Labels

Thermal transfer ribbons (TTR) are the preferred printing method for film labels, delivering high-contrast, long-lasting print quality. Different ribbon types are optimized for various film materials:

Resin Ribbons

Best for: PET, PP, and other high-performance films

Features: High-temperature resistance (150°C+), chemical/oil resistance, scratch-proof

Applications: Automotive part labels, electronic component ID, chemical drum labels

Wax-Resin Ribbons

Best for: PE, PVC, and flexible film labels

Features: Balanced durability and flexibility for curved/bendable surfaces

Applications: Food packaging, logistics labels, medical device labels

Wax Ribbons

Best for: Short-term, cost-sensitive film labels

Features: Economical but less durable

Applications: Warehouse management, temporary promotional labels

about product

Printing Performance on Film Labels

High Resolution: Produces sharp text, barcodes (1D/2D), and graphics with ≥99.9% scan rates.

Longevity: Resin-based prints remain legible for years without fading.

Environmental Resistance: Withstands extreme temperatures (-40°C–150°C), humidity, and UV exposure.

Chemical Resistance: Ideal for oily, solvent-rich, or acidic/alkaline environments.

FAQ